The Innovative Force of the Milling Industry

As Tanış A.Ş., we have been serving as a global manufacturer and solution provider in the field of mill and grain processing technologies since 1956. With our Gaziantep-based production facilities and international sales network, we export to more than 60 countries across 5 continents. Our company, which offers innovative equipment and turnkey solutions for flour, semolina, bulgur, and corn processing facilities, is a leader in the industry with its customer-focused approach, advanced technology products, and reliable service understanding. With our experience of more than 60 years, more than 150 employees, and modern production facilities with 30,000 m² of closed area, we are shaping the future of the milling industry.

- Establishment: 1956, Gaziantep

- Field of Activity: Mill and grain processing technologies manufacturing

- Number of Employees: 450+

- Production Facility: 40,000 m² closed area

- Export: 60+ countries, 5 continents

- Production Capacity: 5,000 tons of machinery and equipment annually

- R&D Center: 2,000 m² area, 50 expert engineers

- References: 1,000+ successful projects

Tanış A.Ş. is Turkey’s leading manufacturer in mill and grain processing technologies and a global solution partner. We provide integrated solutions for every stage of the grain processing process, from cleaning and conditioning systems to grinding equipment, from packaging systems to conveying and automation solutions.

In our modern production facilities in Gaziantep, we develop and produce high-quality products with our advanced technology machinery park and experienced engineering team. We not only provide equipment to our customers but also offer end-to-end support including project planning, facility design, installation, commissioning, operator training, and after-sales services.

As a globally recognized and trusted brand, we contribute to the development of the milling industry with our emphasis on customer satisfaction, commitment to continuous innovation, and superior engineering solutions. Our company, which successfully represents Turkish engineering and production quality worldwide, strengthens its position in the industry day by day with its sustainable growth strategy.

- Quality and Excellence: We aim for the highest quality standards in every product we manufacture and every service we provide, aiming to achieve excellence through continuous improvement.

- Innovation: We embrace change, invest in R&D and innovation, and develop technologies that shape the future of the industry.

- Customer Focus: We best understand our customers’ needs and expectations, provide value-creating solutions, and establish long-term trust-based relationships.

- Reliability: We fulfill our commitments, adopt honest and transparent business practices, and are recognized as a consistent and reliable business partner.

- Respect and Cooperation: We respect our employees, customers, suppliers, and society, and aim for common success with cooperation and participatory approach.

- Sustainability: We consider economic, environmental, and social sustainability and take responsibility to leave a more livable world for future generations.

To provide innovative technologies and integrated solutions that will enable our customers to achieve their efficiency, quality, and profitability goals in the milling and grain processing industry. To guide development in the industry and create sustainable value with our advanced engineering expertise, customer-focused approach, and reliable service understanding.

In line with our mission, we develop customized solutions by understanding the unique needs of our customers and guarantee the long-lasting and efficient operation of our equipment with our production approach that does not compromise on quality. Our business model based on mutual trust and long-term cooperation ensures that we are not just suppliers to our customers but strategic solution partners.

To become a globally leading and innovative brand in milling and grain processing technologies, to reach a position recognized for solutions that determine the latest technologies and trends in the industry and add value to customers.

In line with our vision, we make continuous R&D investments, integrate digital transformation and Industry 4.0 applications into our products, and strengthen our presence in international markets. We work with the goal of being an innovation leader that shapes next-generation milling technologies and contributes to the sustainable development of the industry.

Foundation and First Steps (1956-1965)

Tanış A.Ş. started its activities with the production of mill spare parts in a small workshop in Gaziantep by Mustafa Tanış. In a short time, it became known for its quality products and reliable service, becoming a preferred supplier for mill facilities in the region.

Growth and Development (1966-1985)

In line with increasing demand, we expanded our production capacity and started manufacturing complete mill equipment beyond spare parts. In 1978, we made our first export to Middle Eastern countries. In 1982, we moved to our new production facility with 15,000 m² of closed area and expanded our product range.

Technological Transformation and Globalization (1986-2005)

In 1986, we implemented our first turnkey mill project. In 1990, we established our R&D department and started developing our patented technologies. In 1992, we strengthened our international presence by expanding into African and Asian markets. In 2005, we opened our current modern production facility with 40,000 m² of closed area.

Digital Transformation and Sustainable Future (2006-Present)

In 2006, we gained official R&D Center status. In 2008, we introduced our Industry 4.0 compatible smart mill technologies to the market. In 2010, we made a difference in the industry by developing our sustainable milling solutions and innovative products that provide energy and water efficiency. Today, we continue on our way as a global brand operating in more than 60 countries across 5 continents.

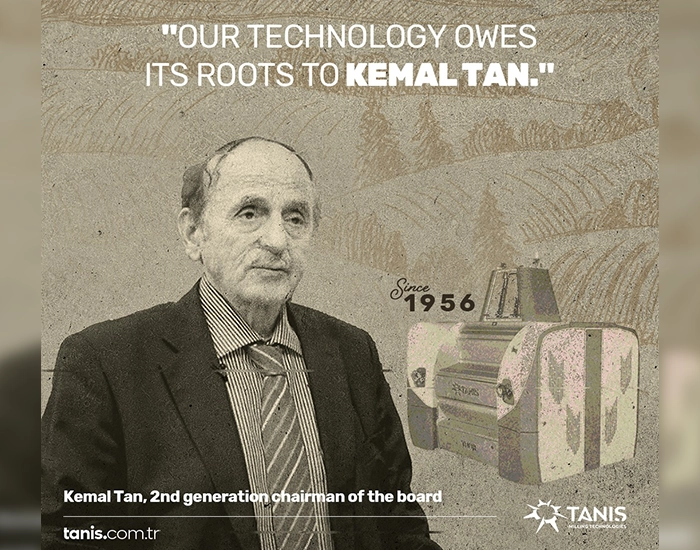

Kemal Tan

Chairman of the Board

With more than 35 years of experience in the milling industry, he is the Chairman of our company’s Board of Directors. He played a pioneering role in Tanış A.Ş. becoming a global brand with his deep knowledge and forward-thinking leadership in the industry.

Emre Tan

CEO

He has more than 20 years of industry experience. He is known for determining the company’s strategic direction and his innovation and global growth-focused vision. He leads digital transformation and sustainable growth initiatives.

Our Facilities and Infrastructure

Tanış A.Ş. operates in modern production facilities with 40,000 m² of closed area in Gaziantep Organized Industrial Zone. We carry out production at the highest quality standards in our facilities equipped with state-of-the-art CNC machines, robotic welding lines, precision metalworking centers, and automatic assembly lines.

Our Production Facilities

Our production facilities are designed in accordance with ISO 9001, ISO 14001, and ISO 45001 standards and operate in accordance with environmental sustainability principles. We take care to minimize our environmental impact with solar energy systems, water recovery units, and waste management systems.

In our Showroom and Customer Experience Center, we offer the opportunity to experience our latest technologies and solutions live. In our training center, we organize special training programs for our customers’ technical personnel.

Our Quality Policy and Certificates

As Tanış A.Ş., we implement a quality management system that centers customer satisfaction and product reliability. Acting with the principle of “Right First Time,” we apply meticulous quality control procedures at every stage of production.

Our Quality Policy

- To produce products at quality standards that exceed customer expectations

- To continuously raise our quality level through continuous improvement and innovation

- To develop our employees’ quality awareness and technical competencies

- To regularly measure and evaluate compliance with quality standards

- To develop quality-focused collaborations with our suppliers

- To be a reference point in the industry with our product and service quality

- ISO 9001:2015 – Quality Management System

- ISO 14001:2015 – Environmental Management System

- ISO 45001:2018 – Occupational Health and Safety Management System

- ISO 50001:2018 – Energy Management System

- CE Certification – European Standards Compliance

- TSE Documents – Turkish Standards Compliance

- ASME Certificate – American Society of Mechanical Engineers Standards

- GOST Certificate – Export Standard for Russia and CIS Countries

As Tanış A.Ş., we place continuous innovation and technological development at the center of our corporate culture. Our R&D Center, which gained official status in 2016, works to develop the latest technologies and solutions in the milling industry.

Our R&D Center

Our R&D Center, operating in a 2,000 m² area, consists of food technology laboratories, material test units, prototype workshops, and simulation center. Our R&D team of 50 expert engineers and technicians works to solve challenges in the industry and develop future milling technologies.

Our R&D Activities

- Development of energy-efficient mill equipment

- Design of conditioning systems that provide water savings

- Industry 4.0 compatible smart mill technologies

- Advanced automation and control systems

- Precision grain processing and quality optimization solutions

- Sustainable milling technologies

We conduct joint research projects with Gaziantep University, transforming academic knowledge into industrial applications. We contribute to increasing sectoral knowledge by providing research opportunities to master’s and doctoral students.

Corporate Social Responsibility

As Tanış A.Ş., we see adding value to society and the environment as our corporate responsibility. We undertake projects that make a difference in education, environment, and social development for a sustainable future.

As Tanış A.Ş., we see adding value to society and the environment as our corporate responsibility. We undertake projects that make a difference in education, environment, and social development for a sustainable future.

Our Education Support Projects

- Future Millers Program: We provide scholarships, internship opportunities, and vocational education support to vocational high school and university students.

- Milling Academy: We organize free technical training programs for industry employees.

- STEM Laboratory Support: We make laboratory donations to local schools that support science, technology, engineering, and mathematics education.

- Green Mill Project: We create sectoral awareness about energy and water efficiency.

- Zero Waste Movement: We provide guidance on waste management and recycling practices in mill facilities.

- Afforestation Campaigns: We plant saplings with the goal of creating 1,000 trees of forest every year.

Our Social Contribution Projects

- Bountiful Tables: We support social projects on food safety and access.

- Employee Volunteer Program: We encourage our employees to participate in social projects, targeting 1,000 volunteer hours per year.

- Barrier-Free Life Support: We contribute to projects that support the participation of disabled individuals in social and economic life.

Tanış A.Ş.’s most valuable asset is human resources. With our 450+ employees, we work as a big family towards common goals, aiming for continuous development and excellence.

Our Human Resources Policy

- A working environment that offers equal opportunities to attract, develop, and retain talent

- Career advancement opportunities with continuous education and development programs

- Performance-oriented, fair, and transparent evaluation and reward systems

- Practices that support work-life balance and employee welfare

- Commitment to diversity, equality, and inclusion principles

- Technical and professional training

- Leadership and management skills development programs

- Digital competencies and information technology training

- Foreign language support

- Academic development opportunities with university collaborations

In line with our “Achieving Together” philosophy, we embrace the culture of teamwork, open communication, mutual respect, and continuous improvement. We value the ideas of each of our employees and encourage innovative thinking and entrepreneurship.