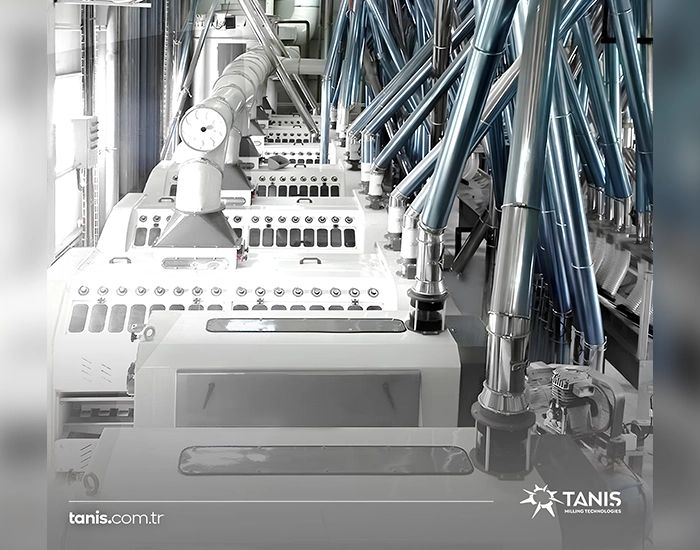

Future Grain Processing Technologies and Innovative Solutions

The milling sector is undergoing rapid technological transformation as a critical link in the global food security and nutrition chain. Today, milling has evolved from simple grinding operations to high-tech intelligent systems. Industry 4.0, digitalization, sustainability, and changing consumer expectations stand out as the main elements shaping the future of the sector. As Tanış A.Ş., with our experience of more than 60 years, we closely follow these trends in the sector and guide the future of the milling industry with our innovative solutions.

Global Milling Industry Size and Growth Rates

The global milling equipment market is valued at approximately $31 billion as of 2025 and is expected to continue growing at an average annual rate of 4.5% over the next five years. The main factors driving this growth include world population increase, urbanization, the rise of the middle class in developing countries, and increasing demand for processed grain products.

Turkey’s Position in Milling Technology

Turkey is among the world leaders in milling technology production and export. Our country has a significant share in milling machinery exports, especially to the Middle East, Africa, and Central Asia markets. Turkish milling technology manufacturers have gained a respectable position in the global market with their innovative designs, competitive prices, and strong service networks.

Key economic factors shaping the milling sector:

- Fluctuations in grain prices and supply security concerns

- Increase in energy costs and sustainability pressure

- Supply chain disruptions and logistics costs

- Rising flour consumption and milling investments in developing countries

- Effects of climate change on agricultural production

- Global trade policies and customs regulations

Impact of Grain Production Developments on the Sector

The increase in grain diversity, new wheat varieties, and the spread of alternative grains (quinoa, amaranth, buckwheat, etc.) require milling technologies to adapt to this diversity. Additionally, the development of new grain varieties resistant to climate change necessitates the optimization of milling equipment for processing these new products.

Industry 4.0 and Digitalization

Milling operations are undergoing digital transformation in accordance with Industry 4.0 principles. The basic elements of this transformation:

- Integrated Digital Systems: Digital infrastructure that connects all stages of production and provides real-time data flow

- Big Data Analysis: Comprehensive analysis of process data to increase operational efficiency

- Digital Twin: Simulation and optimization capabilities with virtual copies of physical milling facilities

- AI-Supported Decision Mechanisms: Intelligent software that increases operational efficiency

Artificial Intelligence and Machine Learning Applications

Artificial intelligence and machine learning technologies are revolutionizing various areas in the milling sector:

- Grain Quality Analysis and Classification: Automatic evaluation of grain quality with optical sensors and machine learning algorithms

- Grinding Optimization: Automatic adjustment of parameters according to changing raw material characteristics

- Predictive Maintenance: Systems that detect and prevent equipment failures in advance

- Product Formulation and Innovation: Development of new flour formulations for customer needs

IoT technology enables these critical applications in milling facilities:

- Real-Time Equipment Monitoring: Sensor networks that continuously track machine performance

- Remote Control and Intervention: Operators’ ability to manage systems without being physically present at the facility

- Energy Consumption Optimization: Real-time tracking and optimization of energy use

- Continuous Monitoring of Quality Parameters: Real-time tracking of factors affecting product quality

Advanced automation and robotic technologies are becoming widespread in these areas in milling facilities:

- Automatic Sampling and Analysis Systems: Automatic collection and analysis of grain and flour samples

- Robotic Packaging and Palletizing: Packaging and stacking operations without human intervention

- Autonomous Warehouse Management: Grain and flour storage operations with autonomous vehicles

- Cleaning and Maintenance Robots: Automatic cleaning and maintenance of milling equipment

Cloud-Based Mill Management Software

Cloud technology offers new opportunities in mill operations:

- Central Data Management: Centralized management of facilities in different locations

- Real-Time Reporting: Instant performance and efficiency reports

- Supply Chain Integration: Integrated systems with customers and suppliers

- Remote Technical Support: Problem solving by service teams with remote access

Augmented reality technology is revolutionizing mill maintenance and training processes:

- AR-Supported Maintenance Guides: Real-time, visual maintenance instructions for technicians

- Remote Expert Support: Expert engineers providing support to field technicians through AR

- Training Simulations: Training operators in virtual environments

- Equipment Performance Visualization: Visualization of performance data of operating equipment

Sustainability and Energy Efficiency Trends

Low Carbon Footprint Milling Systems

Initiatives to reduce carbon footprint in the milling sector are accelerating:

- Carbon Neutral Mill Facilities: Facility designs targeting net zero emissions

- Life Cycle Assessment (LCA): Complete analysis of environmental impacts of equipment

- Green Supply Chain Management: Selection of low-carbon materials and components

- ISO 14067 Carbon Footprint Certification: Emission tracking compliant with international standards

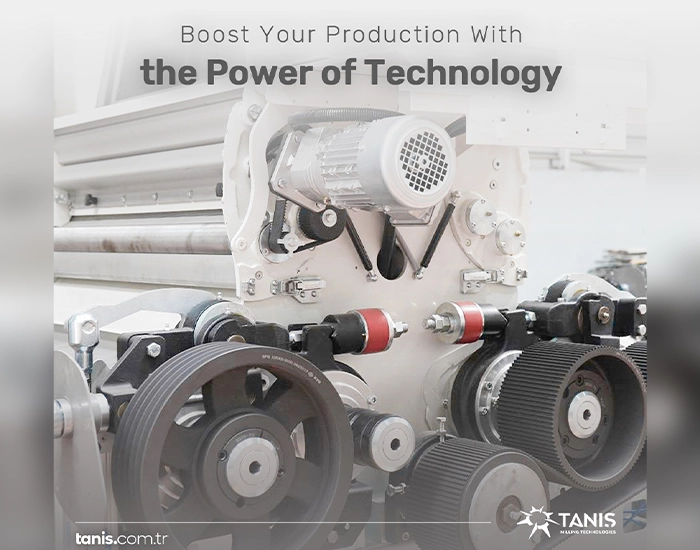

New generation grinding technologies that reduce energy consumption:

- High Efficiency Class Motors: Energy-efficient motors with IE4/IE5 standards

- Smart Mill Control: Artificial intelligence systems that optimize energy consumption

- Regenerative Brake Systems: Technologies that recover braking energy

- Smart Power Distribution Systems: Systems that optimize load balancing and energy flow

Innovative Approaches to Reduce Water Consumption

Solutions developed for efficient use of water resources:

- Dry Cleaning Technologies: Grain cleaning systems that do not use water

- Water Recovery Systems: Treatment and reuse of process water

- Precise Water Dosing: Systems providing optimum water use in tempering process

- Water Footprint Tracking: Detailed tracking of water use in production processes

Waste Management and Recycling Solutions

Innovative approaches for utilizing mill waste:

- Bran Valorization Technologies: Converting bran and other by-products into high-value products

- Biogas Production: Energy production from organic waste

- Compost and Fertilizer Production: Agricultural use of organic waste

- Packaging Recycling Programs: Sustainable packaging solutions

Renewable Energy Integration

Renewable energy use in mill facilities is increasing:

- Solar Energy Systems: Roof and ground-mounted photovoltaic systems

- Biomass Power Plants: Energy production from grain waste

- Hybrid Energy Systems: Integrated energy production from different renewable sources

- Energy Storage Solutions: Storage of produced renewable energy

Product Quality and Food Safety Trends

Advanced Quality Control Systems

Systems that continuously monitor and control product quality:

- NIR (Near Infrared) Analysis Technology: Real-time protein, moisture, and gluten analysis

- Image Processing Systems: Automatic evaluation of product visual characteristics

- Rheological Analysis Automation: Continuous measurement of dough behavior

- Standard Deviation Reduction Technologies: Systems ensuring consistency in quality parameters

Advanced systems for ensuring food safety:

- Advanced Metal Detectors and X-Ray Systems: Detection of foreign materials

- HEPA Filtration Systems: Prevention of microbial contamination

- UV-C Disinfection Technology: Elimination of microorganisms

- Antimicrobial Surface Technologies: Prevention of microbial growth on equipment surfaces

Traceability systems developed for transparency and trust:

- Blockchain-Based Traceability: Uninterrupted tracking chain from grain to flour

- QR Code Integration: Consumers’ ability to view product history

- Real-Time Monitoring with IoT Sensors: Continuous tracking of product conditions

- Supply Chain Transparency Platforms: Tracking systems accessible to all stakeholders

Mycotoxin Detection and Elimination Methods

Developing technologies for managing mycotoxin risk:

- Rapid Mycotoxin Test Kits: Analysis systems providing results within minutes

- Spectroscopic Detection Methods: Continuous mycotoxin tracking during grain processing

- Biological Decontamination Methods: Enzymatic mycotoxin degradation techniques

- Selective Separation Technologies: Automatic separation of contaminated grains

Increasing Demand for Whole Grain and Functional Flour Products

Trends shaped by increasing consumer health awareness:

- High Fiber Grinding Technologies: Systems that preserve the nutritional value of whole grain flours

- Processes Enhancing Mineral and Vitamin Retention: Techniques maximizing micronutrients

- Functional Component Integration Systems: Production of flour enriched with protein, antioxidants, and prebiotics

- Ancient Grain Processing Technologies: Grinding systems for special grains like einkorn, kamut, amaranth

Gluten-Free and Special Nutrition Products Trend

Technologies responding to special nutritional needs:

- Cross-Contamination Prevention Systems: Completely isolated lines for gluten-free production

- Alternative Grain Processing Equipment: Special systems for processing rice, corn, buckwheat

- Protein Enrichment Technologies: Systems that increase protein content of gluten-free flours

- Allergen-Free Production Protocols: Equipment designs developed for allergen management

Consumer interest in local and special products also affects milling models:

- Micro Mill Systems: Compact mills capable of small-scale, flexible production

- Innovations in Stone Mill Technology: Systems combining traditional and modern technologies

- Local Variety Adaptation: Equipment adjustable for regional grain varieties

- Low Volume Premium Production Technologies: Production of high value-added special flours

New Business Models in Mill Operations

Digital Platforms and E-commerce Integration

New business models offered by the digital world:

- B2B E-commerce Platforms: Digital marketing and sales of mill products

- Customer Relationship Management Systems: Customer interaction and service delivery in digital environments

- Mobile Order and Tracking Applications: Custom mobile application solutions for customers

- Digital Marketing Strategies: Creating brand value through social media and content marketing

Transition from traditional equipment sales to service models:

- Pay-per-Use Models: Pricing systems based on production volume

- Remote Monitoring and Maintenance Services: Proactive service and maintenance solutions

- Performance-Guaranteed Contracts: Service agreements focused on efficiency and quality

- Integrated Software Solutions Subscriptions: Service-based provision of mill management software

Data Analytics-Based Decision-Making Processes

Widespread adoption of data-driven business models:

- Business Intelligence Platforms: Systems that analyze and visualize mill operations

- Predictive Analytics: AI systems making production and demand forecasts

- Performance Indicator Monitoring Systems: Digital solutions for KPI tracking and analysis

- Strategic Decision Support Systems: Data analysis supporting investment and operational decisions

Expected Developments in the Next 5-10 Years

Main trends that will shape the milling sector in the medium term:

- Fully Autonomous Mill Facilities: Smart mills operating with minimal human intervention

- Integrated Food Production Ecosystems: Integration of milling and bakery technologies

- Product Development for Personalized Nutrition: Special flour formulations according to individuals’ genetic and health profiles

- Carbon-Negative Mill Operations: Mills creating positive environmental impact with carbon capture and offset technologies

Changing Workforce Profile and Competency Needs

Effects of digital transformation on the workforce:

- Mill Operators with Digital Competencies: New positions requiring software and data analysis knowledge

- Remote Work and Virtual Collaboration: Mill management without being physically present at the facility

- Continuous Education and Skill Development: Lifelong learning for adaptation to rapidly changing technologies

- Human-Machine Collaboration: Skills for working in collaboration with robots and artificial intelligence

Developing market areas for milling technologies:

- Modernization in Developing Economies: Transformation of existing traditional mills

- Customized Solutions: Systems adapted for local grain varieties and preferences

- Compact and Modular Systems: Suitable solutions for small and medium-sized enterprises

- Integrated Training and Support Services: Markets focused on technical knowledge and capacity development

Tanış A.Ş.’s Approach to Sector Trends

Our R&D and Innovation Strategy

As Tanış A.Ş., we closely follow innovations in the sector and focus our R&D efforts in the following areas:

- Smart Mill Technologies: Industry 4.0 compatible, AI-supported mill systems

- Energy-Efficient Solutions: New generation equipment that minimizes energy consumption

- Sustainable Production Systems: Technological innovations that reduce environmental impacts

- Special Flour Production Technologies: Flexible systems responding to changing consumer demands

As Tanış A.Ş., we offer our customers not just equipment, but preparation for the future:

- Technological Transformation Consulting: Digital transformation roadmap and support

- Competency Development Programs: Advanced technology training for technical teams

- Sustainability Assessment: Environmental impact analysis and improvement plans

- Market Trend Analysis: Insights on sector trends and consumer preferences

Resources and Further Reading

To learn more about the milling sector:

- Sector Reports: International Milling Association, Milling Industry Analysis Reports

- Academic Publications: Journal of Cereal Science, Journal of Food Engineering

- Events: International Milling Conference, Milling Technologies Fair

- Tanış A.Ş. Resources: Technical Bulletins, Webinars