Future Mill Technologies

While traditional milling is an art as old as human history, it is rapidly transforming today through technological innovations. The way to gain competitive advantage in the modern flour sector is by adopting innovative technologies and increasing efficiency at every stage of the value chain. Mill operations are making innovation a strategic priority in the face of increasing food demand, changing consumer expectations, and sustainability requirements. In this content, we will examine in detail the latest technological developments in the flour sector, product innovations, and future mill technologies.

Advanced Grinding Technologies and Equipment

Innovations in grinding technology increase energy efficiency while enhancing product quality. New generation roller technologies, specialized groove designs, and precise pressure control can increase yield by 3-5%. Smart roller systems equipped with micro sensors provide optimum performance by making automatic adjustments according to wheat hardness.

Energy-efficient sifting systems offer up to 25% energy savings compared to conventional systems while providing more precise particle size control. Advances in vibration optimization and flow dynamics increase sifting efficiency while reducing maintenance needs.

Micronized grinding systems are revolutionizing the production of special-purpose flours. Ultra-fine grinding technology provides ideal particle size distribution for functional flours and special applications. This technology is particularly preferred for functional foods, nutraceuticals, and premium flour products.

Process Optimization and Efficiency Improvement

Advanced modeling and simulation techniques are used for process optimization in modern mill facilities. Flow dynamics analyses enable the detection of bottlenecks and optimization of production lines. As a result, total efficiency can be increased by 8-12%.

Quick changeover systems minimize transition times between production of different flour types. With automatic cleaning systems and digital recipe management, transition time can be reduced by up to 60%. This flexibility enables mills to respond quickly to changing market demands.

Energy efficiency is one of the most critical elements of modern milling. IE4 and IE5 class super premium efficient motors consume 15-20% less energy compared to conventional motors. Variable frequency drives (VFD) and smart motor control systems optimize energy consumption according to operational needs.

Energy recovery systems capture heat released from process equipment and use it for the facility’s heating or hot water needs. Advanced heat exchangers and thermal storage systems significantly increase energy efficiency.

Integrated energy management systems monitor the facility’s energy consumption in real-time and identify optimization opportunities. These systems are ISO 50001 energy management standard compliant and provide data analysis for continuous improvement.

Digitalization and Smart Factory Solutions

Process Automation and Control Systems

Advanced SCADA systems that integrate all production processes are becoming standard in modern mill facilities. These systems enable monitoring and management of all operations from a single control center. Cloud-based SCADA solutions offer remote access and monitoring capabilities, increasing operational flexibility.

Recipe management systems ensure consistency in the production of different flour types while minimizing operator errors. Digital recipes automatically adjust according to raw material characteristics, ensuring standard product quality even under variable conditions.

Integrated control architectures combine all subsystems of the mill facility (cleaning, tempering, grinding, packaging) on a single platform. This integration optimizes data flow, providing faster decision-making and troubleshooting opportunities.

Industrial Internet of Things (IIoT) is ushering in a new era in mill facilities. Smart sensors continuously monitor critical equipment temperature, vibration, pressure, and performance parameters. Wireless sensor networks reduce installation and maintenance costs while providing a more flexible monitoring infrastructure.

Real-time data collection and analysis systems provide critical insights to increase operational efficiency. With edge computing technology, data is processed at the device level, minimizing latency and enabling instant intervention.

Preventive maintenance systems predict equipment failures in advance, preventing unplanned downtime. Machine learning algorithms analyze equipment “health status” to proactively determine maintenance needs. This approach can reduce maintenance costs by 25-30%.

Big Data and Analytics Applications

Big data and analytics applications in mill operations strengthen strategic decision-making processes. Data mining for process optimization detects correlations between production parameters and determines optimum operating conditions.

Quality prediction models analyze raw material characteristics and predict the quality parameters of the final product in advance. These models enable proactive optimization of process settings, ensuring quality consistency.

Business intelligence (BI) solutions integrate operational and financial data to provide comprehensive performance reports and dashboards. These tools support management in making strategic decisions in a data-driven manner.

Functional and Enriched Flours

Functional flours stand out as innovative products with high nutritional value and health benefits. Vitamin and mineral-fortified flours are becoming an important tool to address micronutrient deficiencies, especially in developing countries.

Protein-enriched flours constitute a rapidly growing segment in the fitness and sports nutrition market. Wheat protein isolation and enrichment techniques with alternative protein sources enable the production of special flours with protein content reaching 25-30%.

Formulations rich in antioxidants and bioactive compounds are attracting interest in the functional food market. Integration of bioactive compounds obtained from bran fractions into flour formulations offers innovative products for health-conscious consumers.

The gluten-free flour market is critically important for celiac patients and those with gluten sensitivity. Advanced processing technologies and product formulations continuously improve the functional properties and sensory quality of gluten-free flours.

Low-carbohydrate flours offer popular alternatives for keto and low glycemic index diets. The technological properties of almond flour, coconut flour, and other alternative flours are being developed with innovative formulation techniques.

Health-focused special flour types offer solutions for specific needs such as cardiovascular health, blood sugar management, and digestive system health. These products are creating a new category at the food-pharmaceutical boundary.

Quality Control and Food Safety Innovations

Advanced Analysis and Testing Technologies

NIR (Near Infrared) spectroscopy is a revolutionary quality control technology in the flour industry. It can analyze protein, moisture, ash, gluten index, and other critical parameters within seconds. Portable NIR devices offer fast and on-site analysis opportunities in raw material acceptance.

Rapid mycotoxin and contaminant detection systems enhance food safety. Immunoassay and biosensor technologies enable detection of dangerous contaminants within minutes.

DNA-based and molecular testing methods provide sensitive solutions for wheat variety verification, gluten contamination, and foreign protein detection. These methods support transparent labeling and verification systems.

In-process continuous quality control is replacing manual sampling and laboratory testing. Inline sensors measure flour characteristics in real-time on the production line and provide instant feedback to control systems.

Automatic sampling and analysis systems eliminate the human error factor, providing more reliable and consistent quality data. These systems facilitate compliance with food safety standards such as GFSI and FSMA.

Parameter deviation detection and correction systems enable instant intervention for quality changes. Statistical process control (SPC) algorithms detect deviations from normal operation and automatically initiate corrective actions.

Sustainable Flour Production and Environmentally Friendly Approaches

Low Environmental Impact Production Technologies

Process innovations that reduce water consumption are critically important for sustainable production in water-stressed regions. Dry cleaning technologies and closed-loop water systems can reduce the water footprint of mill facilities by 40-50%.

Energy efficiency and carbon footprint reduction initiatives increase the environmental sustainability of the industry. Leading mill facilities are setting carbon-neutral production targets by 2030.

Waste minimization and resource optimization are fundamental elements of sustainable flour production. Advanced logistics and inventory management systems reduce raw material waste, while utilization of by-products contributes to zero waste goals.

Innovative use of bran and other mill by-products creates economic value while supporting environmental sustainability. Extraction of bioactive compounds enables the production of high-value nutritional supplements from bran.

Using by-products for bioenergy production contributes to the energy independence of mill facilities. Biogas and biomass systems convert organic waste into renewable energy, reducing carbon footprint.

Circular economy models encourage the utilization of mill by-products in food, feed, cosmetics, and other industries. This approach creates synergy between economic sustainability and environmental responsibility.

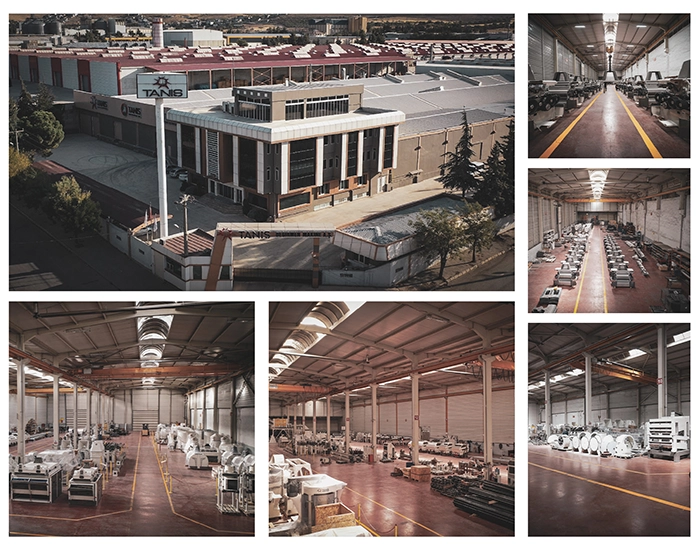

Tanış A.Ş.’s Innovation Approach and Solutions

Our R&D and Innovation Strategy

As Tanış A.Ş., we lead the transformation of the flour sector with our customer-focused innovation approach. In our R&D center, we develop innovative solutions in energy efficiency, digitalization, product quality, and sustainability areas.

Our technology partnerships and collaborations enable us to offer the latest developments in the global innovation ecosystem to our customers. Our strategic partnerships with universities, research institutions, and technology start-ups continuously strengthen our innovation capacity.

Our Innovative Product and Technology Portfolio

Our EnergyOptimize™ smart energy management system provides up to 30% energy savings in mill facilities while significantly reducing carbon footprint. This system monitors and optimizes energy consumption in real-time, supporting the achievement of sustainability goals.

Our MillConnect™ digital platform solution offers the opportunity to monitor, analyze, and optimize mill facility performance through the cloud. With mobile applications and web interface, it provides access to managers and operators from anywhere they want.

Our QualityPredict™ AI-supported quality prediction system analyzes raw material characteristics, predicts final product quality in advance, and automatically optimizes process parameters. This system increases quality consistency while reducing waste rates.

Our Joint Innovation Approach with Customers

We actively involve our customers in our innovation processes, developing solutions focused on real needs. Customer needs and feedback form the foundation of our product development roadmap.

Through pilot application and testing collaborations, we validate our new technologies under real operational conditions, providing risk-free technology adaptation. This approach facilitates our customers’ confident adoption of innovation.

Frequently Asked Questions

Technologies that provide the highest competitive advantage include: energy efficiency solutions (15-30% cost savings), digital control and automation systems (efficiency improvement and quality consistency), quality control and traceability technologies (product reliability and customer trust), and special flour formulations (market differentiation and premium pricing).

Energy efficiency technologies typically provide ROI within 1-3 years, automation systems within 2-4 years, quality control technologies within 2-3 years, and special product innovations within 1-2 years. However, these periods may vary according to the specific conditions of each facility. As Tanış A.Ş., we support investment decisions by providing customer-specific ROI analyses.

Conclusion and Call to Action

Innovation in the flour sector is no longer a choice but a necessity for sustainable competition. Changing consumer demands, sustainability requirements, and digital transformation are shaping the future of the sector. As Tanış A.Ş., we are proud to be a strategic partner for our customers in this transformation journey.