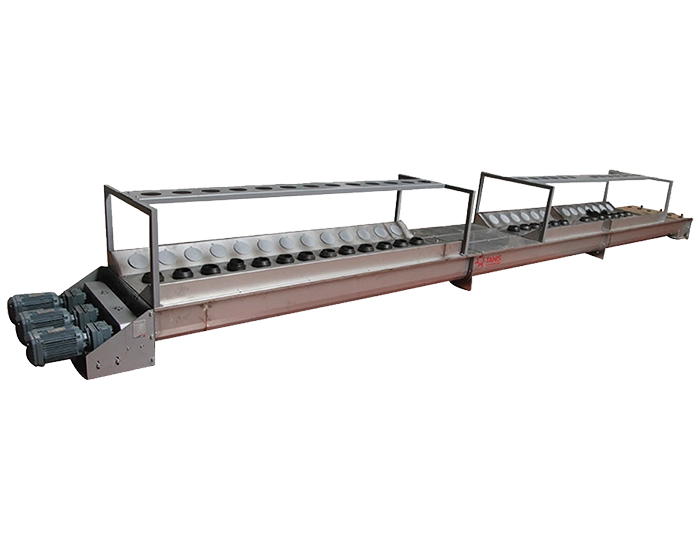

Flour Collection Screw Conveyor

Flour Screw Conveyor: Efficient and Precise Flour Transfer in Mills

In the modern milling sector, preserving the quality of produced flour and transferring it efficiently is of critical importance for product quality and operational efficiency. Flour Collection Screw Conveyor systems developed by Tanış A.Ş. offer hygienic and precise transfer solutions specially designed for collecting and transporting flour after grinding. These systems, which stand out with minimum product loss, low dust emission, and high hygiene standards, are indispensable equipment for modern mill operations.

A flour collection screw conveyor is a special conveyor system designed for collecting, homogenizing, and transporting flour from roller mills and sieves to packaging or storage areas in the milling process. This system works on the principle of a spiral-shaped screw rotating in a closed housing and transports flour precisely and controllably.

Its strategic importance in the final stages of the milling process is significant. After grinding and sifting operations, flour collected at different points needs to be brought together while preserving its quality and without disrupting its homogeneity. The flour collection screw conveyor, in this critical task, collects flour from different exit points into a main line, ensuring a quality and consistent mixture is obtained.

The impact of flour collection and transfer operations on quality is direct. Inappropriate transport systems can cause flour particles to be damaged, increase contact with oxygen, and consequently cause oxidation. Additionally, an inadequate collection system can lead to lumping and homogeneity losses in flour. The flour collection screw conveyor minimizes these risks through its gentle transport principle, ensuring flour quality is preserved.

Advantages in flour transport compared to other transport systems include low energy consumption, minimum dust emission, closed system design, and preservation of product quality. Compared to pneumatic transport systems, it consumes less energy and causes less damage to flour particles. Compared to open conveyor systems, it minimizes dust emission, both preventing product loss and maintaining workplace cleanliness.

Screw design specialized for flour collection forms the heart of this system. Unlike standard screws, flour collection screws have spiral geometry, pitch distance, and rotation speed suitable for the physical properties of flour. This special design ensures flour is transported without compression, lumping, or quality deterioration.

Spiral structure optimized for precise flour transport provides both efficient flour transfer and minimum product damage. Spiral diameter, pitch, and thickness are designed in ideal ratios for flour transport. This precise engineering guarantees even distribution of flour on the spiral and advancement at equal speed.

The working mechanism in flour collection and transfer is simple but effective. The screw (spiral) driven by an electric motor pushes flour forward with its rotating movement. Flour advancing inside the closed housing does not contact the external environment until it reaches the exit point. Inlet and outlet mouths, thanks to their special designs, both provide smooth flour flow and prevent dust leakage.

Closed system advantages providing minimum product loss are of great importance economically and hygienically. The completely closed design prevents flour particles from leaking to the external environment, both minimizing product loss and maintaining workplace cleanliness. Over 95% product preservation is achieved compared to standard open systems.

Gentle transport technology that preserves flour quality is one of the most valuable features of the system. The spiral operating at low speed applies minimum mechanical stress to flour particles. This way, the granular structure of flour is preserved while heat generation is also minimized. As a result, flour’s color, taste, and baking properties are preserved unchanged during transfer.

Spiral design and material properties compatible with flour are optimized for product quality and system durability. Spirals are manufactured from stainless steel suitable for food contact or carbon steel with food-grade coating. The spiral profile is designed according to the “gentle transport” principle to move flour forward without compression or mixing.

Housing structure providing dust-proofing offers environmental advantages. Leak-proof connection points and special gasket systems prevent even the finest flour particles from escaping. This way, both product loss is prevented and workplace air quality is maintained. Housing material options include galvanized steel or stainless steel depending on the application.

Collection hopper and feeding point characteristics are critical components determining system performance. The wide-surface collection hopper ensures flour from different sources comes together smoothly. Feeding points are specially designed for homogeneous flour flow. Multiple inlet mouths can be customized according to mill system design.

Wear-resistant surface treatments and coating provide long-life operation. Surfaces exposed to wear are strengthened with special processes or designed as easily replaceable parts. All metal surfaces undergo processes that provide protection against corrosion, maximizing system life.

Technical Specifications and Performance Parameters

Tanış Flour Collection Screw Conveyor systems are offered in various sizes to meet different capacity needs. Basic technical specifications are as follows:

| Model | Spiral Diameter (mm) | Capacity (tons/hour) | Motor Power (kW) | Maximum Length (m) | Housing Material |

|---|---|---|---|---|---|

| TMUH-150 | 150 | 4-7 | 1.1-2.2 | 8 | Galvanized/Stainless |

| TMUH-200 | 200 | 8-12 | 2.2-3 | 10 | Galvanized/Stainless |

| TMUH-250 | 250 | 15-20 | 3-4 | 12 | Galvanized/Stainless |

| TMUH-300 | 300 | 25-35 | 4-5.5 | 15 | Galvanized/Stainless |

Features included as standard in all our models:

- Materials compliant with food safety standards

- Leak-proof connection points and dust control

- Access doors for easy cleaning

- High-efficiency IE3 class motors

- Adjustable support legs

- Modular and easy assembly design

- Multiple inlet mouth options

Motor power and energy consumption values are optimized according to system length and transport capacity. High-efficiency motors and direct drive mechanism are used for energy efficiency. This way, 60-70% less energy is consumed compared to pneumatic transport systems.

Flour transport capacity and speed options are determined according to mill needs. Spiral rotation speed can be optimized according to flour type and transport distance. Generally, the principle of operating at low speeds is adopted to preserve flour quality.

Model Varieties and Capacity Options

Model alternatives for different mill capacities offer suitable solutions for every scale of operation. While the UTH-150 series is ideal for small-scale mills, the UTH-300 series is preferred for large industrial facilities. Each model has motor power optimized according to capacity and transport distance.

Various length and diameter options adapt to facility layout. Standard lengths can be manufactured starting from 3 meters up to 15 meters depending on the model. For longer transport needs, multiple system configurations can be designed. Spiral diameter selection is made according to transport capacity and flour type.

Specialized versions for different flour types are available. Models with optimized spiral pitch and profile are offered for different characteristic products such as fine flour, whole wheat flour, and special purpose flours. Special hygienic designs and easy-to-clean versions have been developed for gluten-free products.

Optional equipment and configuration alternatives increase system flexibility. Options such as automatic lubrication systems, digital control panels, level sensors, speed control units, heating/cooling jackets respond to special application needs. Configuration alternatives offer customized solutions for each facility.

Hygiene and Food Safety Standards

Structure specially designed for food safety is the most important feature of the Flour Collection Screw Conveyor system. All surfaces in contact with food are manufactured from materials compliant with international food safety standards. System design is made to minimize product accumulations and microbial development points.

Closed system advantages preventing flour contamination guarantee product safety. The completely closed transfer environment keeps out airborne contamination, insect and rodent threats, and other physical contaminants. This protection is of great importance especially in food businesses with high hygiene expectations.

Material properties of surfaces in contact with food are the foundation of food safety. Stainless steel or food-grade coating materials provide corrosion resistance, easy cleanability, and microbial accumulation resistance. All welding points and connections are designed smooth and gapless according to food standards.

Easy-to-clean design and hygiene control points facilitate regular maintenance and sanitation operations. Access doors placed at strategic points enable cleaning and inspection of the system’s internal parts. Easily removable parts allow comprehensive cleaning operations.

Compliance with FDA, HACCP, and other food safety standards determines system reliability. Tanış Flour Collection Screw Conveyor is designed and manufactured in full compliance with these standards. The system meets the requirements of food safety management systems and performs highly in food safety audits.

Cleaning and Sanitation Features

Design details for quick and easy cleaning increase operational efficiency. Access doors that can be opened without tools provide quick and easy cleaning capability. Smooth design on internal surfaces prevents product accumulation and increases cleaning effectiveness. These features minimize the time required for sanitation, increasing production efficiency.

Surfaces that prevent bacteria and microorganism formation strengthen food safety. Antimicrobial coatings, smooth surfaces, and inclined designs that prevent water accumulation prevent microbial development. These features are of critical importance especially in systems operating in humid environments.

Access doors for periodic cleaning provide easy access to all internal components. These doors placed at strategic points allow effective cleaning of every point of the system. Sufficient size and number of access points are available for complete cleaning of spiral and housing.

Cleaning procedures and recommendations preserve system performance. Tanış provides a detailed cleaning and sanitation guide with each Flour Collection Screw Conveyor. This guide includes daily, weekly, and monthly cleaning routines, appropriate cleaning materials and methods to be used. Proper cleaning procedures both extend system life and guarantee product safety.

Flour Quality Protection and Product Property Preservation

Preserving flour texture through gentle transport is of critical importance for product quality. Tanış Flour Collection Screw Conveyor applies minimum mechanical stress to flour particles thanks to its low-speed and precise spiral design. This way, the granulometric structure of flour is preserved and flour properties that directly affect the quality of final products such as bread and pastry are maintained.

Minimum oxidation and air contact preserve flour freshness. Closed system design minimizes flour’s contact with air, slowing oxidation and consequently flour aging. This protection is of great importance especially in products expected to have long shelf life.

The ability to transfer while preserving mixture homogeneity provides consistent product quality. Transporting the homogeneous mixture obtained after flour blending without deterioration is essential for the consistency of final product quality. Flour Collection Screw Conveyor guarantees homogeneous transfer without disrupting mixture properties.

Advantages of preserving flour properties and nutritional values are important for healthy and quality product production. Thanks to low-stress transport, minimum oxidation, and temperature control, flour’s protein structure, enzyme activity, and vitamins are preserved. This preservation positively affects the nutritional value and baking properties of bread and flour products.

Maintenance and Service Ease

Durable design requiring minimum maintenance reduces operating costs. High-quality materials, precise engineering, and solid structure minimize maintenance needs. Wear-resistant components provide long service intervals, reducing maintenance costs and production downtime.

Easily accessible service points and control doors provide quick intervention capability. Service doors placed at strategic points provide easy access to critical components such as spiral, bearings, and sealing elements. This feature shortens maintenance time, increasing production efficiency.

Wear control and periodic maintenance recommendations extend system life. Tanış provides a detailed maintenance guide with each Flour Collection Screw Conveyor. This guide includes daily, weekly, and monthly control points, lubrication requirements, and wear indicators. Proactive maintenance approach prevents unexpected failures, increasing system reliability.

Spare parts supply and quick service support guarantee operational continuity. Tanış provides quick supply capability by keeping all spare parts continuously in stock. Technical service team provides solution to problems with quick intervention in emergency situations. 24/7 technical support line provides uninterrupted assistance to customers.

Frequently Asked Questions

At which points should I use flour collection screw conveyor?

Flour collection screw conveyor is generally used in the final stages of the milling process for collecting, blending, and transferring flour from roller mill units and sieves to packaging or storage units. It is especially ideal at points where different quality flours are brought together to ensure homogeneous mixture.

Can the same system be used for different flour types?

Yes, but different flour types may show different flow characteristics. Parameters such as spiral speed and fill ratio may need to be adjusted for fine flours, whole wheat flours, or special purpose flours. In facilities producing very different flour types, it is recommended to use separate systems optimized for each product group.

What should the cleaning frequency be?

Under standard operating conditions, weekly visual inspection and monthly comprehensive cleaning are recommended. Additional cleaning should be done during shift changes or transitions to different flour types. In applications requiring allergen control such as gluten-free products, comprehensive cleaning is mandatory at every product change.

What should I pay attention to in capacity selection?

In capacity selection; daily flour production amount, peak flow rates, flour input amounts at different points, and future capacity increase plans should be considered. For optimal performance, it is recommended that the screw operates at 30-40% fill ratio. Overloading increases energy consumption while potentially damaging flour quality.

What is the maximum transport distance?

Maximum transport distance for single-piece flour collection screw conveyor varies between 8-15 meters depending on the model. For longer distances, special designs with intermediate bearings or series-connected systems can be used. In long-distance applications, correct selection of spiral diameter and motor power is of critical importance.

To get more detailed information about Tanış Flour Collection Screw Conveyor systems to optimize your mill’s flour collection and transport processes, preserve your product quality, and increase your efficiency, please contact us. Our expert team is ready to offer customized solutions for your needs.