Semolina Breaker

Precision Semolina Processing and Controlled Grinding Technology

In the modern milling industry, the semolina processing stage is a critical step for high-quality production, optimized by Tanış A.Ş.’s advanced Semolina Crusher technology. Equipped with high-precision processing capacity and advanced control systems, this equipment plays a key role in maintaining consistent efficiency and quality in milling operations. With over 60 years of experience in grain processing, Tanış A.Ş. continuously develops the Semolina Crusher to meet the demanding requirements of modern milling.

The semolina processing process, one of the critical stages of quality flour production in the modern milling sector, has been optimized with Tanış A.Ş.’s innovative Semolina Breaker technology. This equipment, equipped with high-precision processing capability and advanced control mechanisms, plays a strategic role in achieving the efficiency and quality goals of mill operations. Tanış A.Ş., with over 60 years of experience in grain processing, continuously develops the Semolina Breaker to meet the challenging requirements of milling.

Semolina Breaker is a special machine that enables the controlled breaking and conversion to flour of semolinas obtained as a result of grinding wheat kernels in the mill process. This equipment, which plays a critical role in the transition from semolina stage to flour stage, has a direct effect on determining final flour quality and significantly increases mill efficiency.

Basic Function and Purpose of Semolina Breaker

The basic function of the Semolina Breaker is to optimally break semolina particles of various sizes coming from rollers and convert them to flour. During this process, the aim is to break semolina particles homogeneously and obtain controlled granulation. Semolina Breaker provides:

- Maximum exposure of endosperm particles within semolina

- Homogeneous processing of semolina particles of different sizes

- Control of parameters affecting flour quality such as starch damage

- Increased overall efficiency by reducing the load on the roller system

- Increased sieve efficiency by reducing semolina particles to optimum size

Semolina Breaker is usually located at the beginning of reduction passages in the mill diagram and has a central role in the efficiency balance of the system. Thanks to this strategic position:

- Increases sifting efficiency by providing homogeneous breaking of coarse semolinas

- Provides higher yield by optimizing flour extraction rate

- Reduces energy consumption by balancing roller load

- Stabilizes production flow by preventing bottlenecks throughout the system

- Provides consistency in final product quality

- Contributes to more efficient use of mill capacity

Position in the Semolina to Flour Conversion Process

In the flour production process, wheat kernels are first opened in break rollers and endosperm and bran parts are separated from each other. At this stage, while part of the obtained semolina is sent directly to sieves, coarser semolina particles are directed to the Semolina Breaker. Semolina Breaker processes these particles by:

- Ensuring maximum conversion of endosperm particles within semolina to flour

- Keeping bran mixing into flour at minimum level

- Helping to obtain a controlled starch damage rate

- Improving rheological properties of final flour

- Enabling different quality flour fractions to be obtained

Semolina processing equipment in milling history has undergone significant evolution from stone mills to modern hammer systems. The semolina breaking process, which was done with simple mechanical systems in early periods, is now performed with high-tech equipment.

Tanış A.Ş.’s modern Semolina Breaker design has been developed as a result of sectoral experience gained over years and comprehensive R&D studies:

- Minimum vibration with precisely balanced rotor system

- Wear-resistant special alloy hammers

- Precise parameter adjustment with digital speed control systems

- Low thermal processing with efficient cooling mechanisms

- Flexibility to work in wide capacity range

- Continuous performance monitoring with smart sensor technology

Machine Body and Structural Features

The body of the Semolina Breaker is manufactured from high-quality ST52 steel construction and designed for continuous operation under harsh industrial conditions:

- 8-10 mm body thickness (varies by model)

- Surface treatment with sandblasting + epoxy primer + topcoat paint

- Easy-opening hydraulically supported covers for quick access

- Vibration absorbing feet to prevent vibration transmission to ground

- Acoustic insulation for operating noise below 85 dB(A)

- Corrosion-resistant material selection and processing techniques

This robust structure ensures long-lasting and trouble-free operation of the equipment, reducing operating costs and extending maintenance intervals.

The rotor and hammer system forming the heart of the Semolina Breaker is the most critical component directly affecting semolina breaking performance:

- Dynamically balanced, high-strength steel rotor

- 350-500 mm rotor diameter (varies by model and capacity)

- Special alloy steel hammers with 58-62 HRC hardness

- 24-64 hammers (varies by model)

- Practical connection system providing quick removal and installation

- Dynamic balance at G6.3 precision level

- Double-sided hammer design usable in 4 different positions

- Maximum efficiency with optimized hammer placement geometry

The rotor is designed in a geometry that guarantees optimum impact angle and effect of each hammer. This ensures homogeneous breaking of semolina particles and obtaining desired granulation.

Tanış Semolina Breaker is equipped with various control mechanisms that can be easily adjusted according to different processing conditions and product characteristics:

- Adjustable rotor speed in 2000-3600 rpm range with frequency inverter

- Precision feed control with rotary valve or vibro feeder

- Desired granulation control with sieves having different hole diameters

- Adjustable air flow for optimum cooling and dust control

- Modern control panel with touch screen (PLC controlled)

- Sensors continuously monitoring temperature, vibration, and current values

- Fast product change opportunity with 50 different recipe storage capacity

Thanks to these adjustable parameters, Semolina Breaker can be easily optimized to achieve desired results in production of different wheat qualities and different flour types.

Since the Semolina Breaker is equipment operating continuously at high speed and due to the abrasive effect of semolina particles, wear resistance of materials used is critically important:

- Hammers are manufactured from special heat-treated steel with 58-62 HRC hardness value

- Inner surface coatings consist of wear-resistant replaceable plates

- Sieve surfaces are manufactured from special material with long life and precise tolerances

- All wear-exposed parts are easily replaceable with modular design

- High-strength bolts and connection elements are used at critical connection points

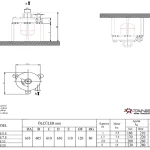

Size and Capacity Options

Tanış Semolina Breaker is offered with various size and capacity options to meet the needs of different sized mill facilities:

| Model | Capacity (kg/hour) | Rotor Width (mm) | Motor Power (kW) | Dimensions (LxWxH mm) |

|---|---|---|---|---|

| TMIK-51/5,5 | 600-1000 | 600 | 5,5 | 1200x800x1100 |

| TMIK-51/7,5 | 900-1500 | 900 | 7,5 | 1500x900x1200 |

| TMIK-51/11 | 1200-2000 | 1200 | 11 | 1800x1000x1350 |

| TMIK-51/15 | 1500-2500 | 1500 | 15 | 2100x1100x1400 |

This wide model range offers a suitable solution for the needs of businesses of every capacity from small-scale mills to large industrial facilities.

Working Principle and Operating Mechanism of Semolina Breaker

Detailed Working System Description

The working system of Tanış Semolina Breaker consists of the following stages:

Feeding: Semolina particles enter the machine from the feeding mouth located at the top. Feed amount is controlled with rotary valve or vibro feeder.

Breaking Process: Hammers on the rotor rotating at high speed hit semolina particles, breaking them into smaller pieces.

Sifting: Broken semolina hits the sieve surface located at the bottom of the rotor. Particles reaching desired size pass through sieve holes, while larger particles are directed back to the rotor.

Discharge: Broken product passing through sieves is directed to the lower chamber and returns to the system from the outlet.

Ventilation: An air flow is provided inside the machine to control heat generated during process. This air flow also helps with dust control.

Physical Foundations of Semolina Breaking Process

The semolina breaking process is basically based on the kinetic energy transfer principle. Hammers on the rotor rotating at high speed provide energy transfer by hitting semolina particles. As a result of this energy transfer, semolina particles:

- Break by hitting hammers

- Break by hitting inner surfaces of machine body

- Break by colliding with each other

- Are filtered by hitting sieve surface

These complex interactions ensure homogeneous processing of semolina particles of different sizes. Process effectiveness is maximized by optimum adjustment of parameters such as hammer speed, feed amount, and sieve opening.

Speed and Control Parameters During Operation

Basic operating parameters affecting Semolina Breaker performance are:

Rotor Speed: Adjustable in 2000-3600 rpm range. Higher speed provides finer breaking, while lower speed offers more controlled process.

Feed Amount: Can vary between 0.5-3 tons/hour (depending on model). Optimum feed amount should be adjusted according to desired product quality and machine capacity.

Sieve Opening: Sieve holes varying between 0.5-2.0 mm can be used. Sieve opening directly affects final product granulation.

Air Flow: Air flow rate can be adjusted for control of heat generated during process and dust management.

The correct combination of these parameters is determined according to semolina type and desired final product characteristics.

Performance and Efficiency Features

Processing Capacity and Energy Consumption

Tanış Semolina Breaker is designed to provide optimum energy efficiency:

- Specific Energy Consumption: 10-15 kWh/ton (depending on processing conditions)

- Motor Load Factor: 70-80% under normal operating conditions

- Efficiency Rate: 15-20% lower energy consumption compared to similar equipment

- IE3 Efficiency Class Motors: High-efficiency motors as standard in all models

Thanks to high-efficiency electric motors and optimized rotor design, Semolina Breaker provides maximum performance with minimum energy consumption.

Product Granulation Control

Semolina Breaker allows precise control of final product granulation:

- Granulation Range: 100-700 microns (depending on sieve selection)

- Granulation Standard: Consistent granulation with ±50 micron tolerance

- Particle Size Distribution: Optimum distribution with Gaussian distribution curve

- Fine Particle Control: Adjustable according to desired fineness level

This precise granulation control enables meeting specific particle size requirements needed in production of different flour types.

Homogeneous Processing Capability

One of the most important performance features of Semolina Breaker is its homogeneous processing capability:

- Equal Energy Distribution: Homogeneous breaking with equal energy distribution along the rotor

- Complete Access: Equal participation of all semolina particles in processing process

- Consistent Output: Product quality that does not change from shift to shift

- Adaptive Processing: Consistent results even under changing feed conditions

This homogeneous processing capability provides standardization in flour quality and guarantees consistent final product characteristics.

Effect on Flour Quality and Technical Parameters

Direct Effects of Semolina Breaker on Flour Quality

Semolina Breaker directly affects flour quality in the following ways:

Particle Size Distribution: Ideal particle size distribution creates positive effect on flour’s water absorption and dough development.

Starch Damage: Controlled breaking process provides optimum starch damage level. This directly affects bread volume and fermentation process.

Protein Quality: Controlled breaking process ensures preservation of protein structure, improving functional properties of flour.

Homogeneity: Having all flour particles with similar characteristics provides consistency in final product quality.

Correct adjustment of Semolina Breaker parameters plays a critical role in optimization of these quality factors.

Protein and Starch Damage Control

Semolina Breaker provides precise control over protein structure and starch damage, which are determinant in flour quality:

Protein Structure: Protein denaturation is minimized with controlled processing. This is critically important especially in bread flours requiring strong gluten structure.

Starch Damage Rate: By adjusting rotor speed and feed amount, ideal starch damage level in 6-12% range can be obtained. This rate directly affects flour’s water absorption and fermentation properties.

Enzyme Activity: Controlled processing ensures preservation of natural enzyme activity, creating positive effect in dough maturation and fermentation process.

Optimization Opportunities for Different Flour Types

Tanış Semolina Breaker is a versatile equipment allowing special adjustments for different flour types:

Bread Flour: Medium speed and fine sieve combination for high protein preservation and controlled starch damage.

Pasta Flour: Low speed and very fine sieve combination for low starch damage and fine particle size.

Pizza Flour: Special parameter settings for medium level protein development and starch damage.

Whole Wheat Flour: Low speed and wide opening sieve to prevent excessive fineness of bran particles.

These optimization opportunities provide mill operators flexibility to offer a wide product range.

Integration and Maintenance

Easy Integration to Mill Line

Tanış Semolina Breaker is designed to be easily integrated into existing mill lines:

- Compact Dimensions: Compact design that can be easily placed in limited spaces

- Standard Connections: Inlet and outlet connections compliant with international standards

- Flexible Placement: Assembly options adaptable to horizontal or vertical flow systems

- Modular Structure: Modular design allowing capacity increase when needed

- Compatible Interfaces: Compatible operation with different transport systems

Maintenance and Service Requirements

Regular Controls:

- Daily: Abnormal sound/vibration control, product quality control

- Weekly: Belt tension, bearing temperatures, connection cleaning

- Monthly: Hammer wear control, bearing lubrication, sieve cleaning

- 6-Monthly: Comprehensive control, necessary part replacements

Wear and Abrasion Control:

- Hammers: Position change every 3-6 months, renewal every 12-18 months

- Sieve Surface: Change every 12-24 months

- Belts: Renewal every 12-18 months

- Bearings: Control and replacement if necessary every 2-3 years

Spare Parts and Service Support

Tanış A.Ş. provides comprehensive spare parts and service support for Semolina Breaker:

- Spare Parts Guarantee: 10-year supply guarantee for all critical parts

- Service Network: Service support within 24 hours throughout Turkey

- Emergency Intervention: On-site intervention within 12 hours for critical failures

- Online Support: Remote diagnosis and troubleshooting service

- Maintenance Contracts: Special contracts including regular maintenance and preventive maintenance services

Frequently Asked Questions

Where should the Semolina Breaker be positioned in the mill diagram?

It is usually positioned at the beginning of reduction passages, after semolina sizers. Tanış engineers provide analysis for the most suitable positioning specific to your facility.

How do we know when hammers need to be replaced?

Decrease in flour quality, change in particle size distribution, increase in energy consumption, and abnormal vibration or sound indicate replacement time. If wear of more than 3 mm is detected in monthly controls, replacement is recommended.

How should Semolina Breaker parameters be adjusted for different flour types?

- Bread Flour: 2800-3200 rpm, 0.8-1.0 mm sieve opening

- Pasta Flour: 2400-2800 rpm, 0.5-0.7 mm sieve opening

- Pizza Flour: 2600-3000 rpm, 0.7-0.9 mm sieve opening

- Whole Wheat Flour: 2200-2600 rpm, 1.0-1.5 mm sieve opening

What is the installation and integration time?

It takes 1-3 days depending on facility size. Integration is performed during planned shutdown periods to minimize production interruption.