Titanius Square Sifter

Titanius Square Sifter: A Revolutionary Solution for Milling

The Titanius Square Sifter developed by Tanış A.Ş., which has been serving the milling sector since 1956, is an innovative solution that increases your grain cleaning efficiency. These unique square-form sieves, produced in our Gaziantep-based production facilities with our experience in wheat, corn, and barley processing equipment, offer superior durability, high capacity, and maximum efficiency.

Titanius Square Sieve is a high-capacity grain sifting system designed in a square shape, unlike traditional circular-form sieves. Its basic structure is a sifting technology equipped with high-vibration and balanced motion mechanism, reinforced with titanium alloy components.

The unique design advantages brought by the square form significantly increase the maximization of sifting surface and area utilization efficiency. While part of the surface area in traditional circular sieves cannot be used effectively, up to 27% more sifting area is provided thanks to the square design.

Titanium reinforcement technology is also the origin of the product’s naming. Titanium alloy technology used in critical structural components provides a long-lasting and robust structure even under high vibration. This reinforcement has been specifically applied at corner junction points where sieves are most stressed and vibration transmission centers.

Among the innovations it offers compared to traditional sieves are balanced vibration distribution, higher capacity sifting ability, easy sieve change system, and long-lasting durability thanks to titanium reinforcement. These features make Titanius Square Sieve a revolutionary solution in the milling sector.

The effect of square form structure on sifting efficiency is fundamentally based on the physical advantages of geometry. The application of horizontal vibration movement to the square form ensures equal distribution of grain across the entire surface and eliminates regions called “dead spots” where no sifting occurs.

Optimum area utilization provides great advantages especially in mills with limited facility space. The square form offers more sifting surface within the same base area and provides more compact placement opportunity in facilities. Additionally, it enables more economical use of standard-sized sieve cloths.

Vibration distribution and balanced movement is one of the most important engineering achievements of Titanius Square Sieve. Thanks to the multi-point driven vibration system, not center-axis driven, equal amplitude vibration distribution is provided across the entire sifting surface. This balance increases sifting efficiency while reducing structural stress.

Structural durability and long life features are achieved with titanium alloy components and optimized design. Special corner reinforcements of the square form maintain structural integrity even at high-frequency vibrations. This provides up to 40% longer service life compared to traditional sieves.

Titanium alloy components are used especially at critical points operating under high vibration. Titanium-steel composite alloys create an ideal engineering solution by offering lightness and durability together. These alloys are strategically positioned at corner junction points, bearing housings, and vibration transmission components.

Superior durability properties against wear are the distinguishing feature of Titanius technology. Vibration-induced fatigue and wear, one of the biggest problems of traditional sieves, has been minimized with special surface treatments and material science applications.

Material engineering for long-lasting operation is applied at every stage of the production process. Heat-treated materials, precision welding technologies, and computer-aided structural analysis optimized components form the foundation of Titanius Square Sieve’s long-lasting performance.

Performance stability under heavy load is critically important in continuously operating mill facilities. Titanium reinforcement offers stable operation even at high vibration frequency and long-term operation opportunity without performance loss.

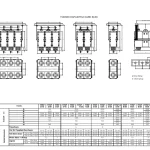

Technical Specifications and Performance Parameters

Titanius Square Sieve is offered in various sizes and capacities:

- Dimensions: 1200x1200mm, 1500x1500mm, 1800x1800mm, 2100x2100mm

- Capacity range: 5-25 tons/hour (depending on model and grain type)

- Sifting layers: 1-3 layer options

- Weight: 450-1200 kg (according to model size)

- Vibration frequency: 850-950 rpm

- Sieve openings: Options between 0.8-7.0 mm

Sieve area and sifting capacity are directly related. The wide surface area of Titanius Square Sieve provides less sieve area requirement per ton compared to traditional sieves. For example, our 2100x2100mm model can offer sifting capacity up to 25 tons/hour.

Vibration motor and movement mechanism work with high-efficiency electric motors and specially designed eccentric weights. The multi-point driven system provides balanced vibration and optimum movement characteristics.

Energy consumption and efficiency values are above industry standards. Titanius Square Sieve, which provides an average of 15-20% less energy consumption per ton, makes a significant contribution to operational economics.

Specially designed insulation systems are used for noise level and vibration control. Elastomer vibration isolators and graduated spring system minimize the transmission of machine vibration to the building and reduce noise level to 80-85 dB range.

Model Alternatives and Size Options

We have model options for different capacity classes:

- TMSP-1200 series: For small mills with 5-8 tons/hour capacity

- TMSP-1500 series: For medium-scale businesses with 8-12 tons/hour capacity

- TMSP-1800 series: For large facilities with 12-18 tons/hour capacity

- TMSP-2100 series: For industrial-scale facilities with 18-25 tons/hour capacity

Scale and size alternatives offer solutions for both compact facilities and wide-area businesses. Single, double, or triple sieve layer options are available for each model.

Selection criteria according to facility size are determined considering processing capacity, existing space constraints, and special cleaning requirements. The Tanış engineering team provides technical support in selecting the most suitable model for your needs.

Sifting Performance and Efficiency Advantages

High-precision sifting capability is one of the fundamental advantages of Titanius Square Sieve. Thanks to balanced vibration distribution and optimum sifting angle, maximum contact of grain particles with the sieve surface is ensured. This feature minimizes the blind passage ratio.

Performance in separating foreign materials of different sizes and qualities is enhanced with multi-layer options. The first layer serves coarse cleaning, the second layer fine particle separation, and the third layer final control function. This configuration offers the opportunity to perform a series of sifting operations in a single unit.

Among the design features that reduce clogging and failure risk are self-cleaning sieve surfaces and optimum vibration amplitude. Specially shaped ball cleaners prevent clogging of sieve holes and provide a continuously clean sifting surface.

Superiority in capacity-efficiency ratio is the competitive advantage of Titanius Square Sieve. It offers up to 30% higher capacity within the same area compared to traditional systems and does not compromise on sifting efficiency.

Test Results and Performance Data

Data obtained from laboratory and field tests confirm the superior performance of Titanius Square Sieve. In tests conducted under controlled conditions, 25-30% higher sifting capacity was measured compared to circular sieves of the same size.

In comparative performance analysis with traditional sieves, the distinct advantage of Titanius Square Sieve was observed especially in high-moisture and dirty grains. Even in wheat with high contamination rates, cleaning efficiency above 98% was achieved.

Efficiency values for different grain types have been verified through comprehensive field tests. Cleaning efficiencies of 98.5% for wheat, 97.8% for corn, and 98.2% for barley have been recorded as average values.

Effect on Grain Quality and Cleaning Advantages

Preservation and improvement of grain quality is one of the fundamental design goals of Titanius Square Sieve. Low impact force and controlled vibration preserve the physical integrity of grain kernels. This feature is critically important especially in seed grain processing.

The effectiveness of removing unwanted materials has been optimized with different sieve openings and configurations. Effective separation of stones, soil, metal parts, other seed types, and broken kernels in grain is ensured.

Cleaning performance for different grain types can be adjusted considering the special characteristics of each grain type. Optimized sieve openings and vibration parameters for wheat, corn, and barley offer maximum cleaning effectiveness.

The positive effect on final product quality is measured by providing clean and homogeneous grain. Effective cleaning reduces equipment wear in subsequent processing steps, increases energy efficiency, and improves final flour quality.

Integration and System Compatibility

Easy integration into existing mill lines is possible thanks to the modular design of Titanius Square Sieve. Standard input-output connections can be easily adapted to existing transport systems. Even in retrofit projects, it requires minimum line changes.

Compatible operation with other cleaning equipment offers the opportunity to create an integrated cleaning line. A comprehensive cleaning system can be created by working in series with stone separators, hullers, and magnetic separators.

Minimum space requirement and placement advantages provide the opportunity to use facility space efficiently. Compact design saves valuable facility space especially in mills with limited space.

Ease of use in modernization projects offers smooth transition opportunity to replace old sifting systems. Generally, upgrades can be made with minimum downtime by preserving existing connection points and support structures.

Installation and Commissioning

Installation process and requirements are managed by the professional Tanış technical team. A standard installation includes the following steps:

- Preparation of suitable location and provision of foundation requirements

- Placement and level adjustment of sieve unit

- Assembly of vibration isolators

- Making electrical and control connections

- Connecting input-output pipelines

- Assembly of sieve surfaces and tension adjustment

Installation ease and fast setup advantages are provided through prefabricated components and modular structure. A typical installation can be completed within 1-2 days and production interruption is minimized.

Commissioning and testing procedures guarantee that the system operates at optimum performance. Vibration measurements, balance control, and flow tests are important steps of the commissioning process.

Initial startup and calibration operations are performed by Tanış engineers. Optimum vibration frequency, amplitude, and sieve angles are adjusted according to grain type and desired cleaning performance.

Usage and Operation Features

Operator-friendly control system offers easy use and monitoring opportunity. Digital control panel enables real-time monitoring and adjustment of critical parameters.

Easily adjustable parameters include vibration frequency, feed rate, and sieve inclination. These adjustments can be optimized according to different grain types and contamination levels.

Daily operation and monitoring routines require minimum operator intervention. Basic controls:

- Normal operating sound and temperature of vibration motor

- Cleanliness of sieve surface and clogging control

- Feed regularity and product flow control

- Condition of vibration isolators

Comprehensive operator training and documentation are provided regarding points to be considered during operation. This training is critically important for optimum performance and long-lasting operation.

Maintenance and Service Ease

Reduced maintenance needs and long service intervals are among the important advantages of Titanius Square Sieve. Thanks to titanium reinforcement and high-quality components, maintenance requirements have been significantly reduced compared to traditional sieves.

Easily accessible maintenance points provide fast and effective service opportunity. Openable covers and modular design offer easy access to critical components.

Sieve change and cleaning procedures can be performed quickly and easily. Quick-changeable sieve cassette design minimizes sieve change time and reduces production interruption.

Spare parts and long-term service support are guaranteed by Tanış A.Ş. All common spare parts are kept in stock and minimum downtime is ensured with fast shipping.

Economic Advantages and Investment Value

Savings potential in operating costs is among the fundamental economic advantages offered by Titanius Square Sieve. Lower energy consumption, reduced maintenance needs, and minimized production interruptions directly contribute to operational economics.

The economic value of long-lasting design is measured by the reduction in renewal and spare parts costs. 2-3 times longer service life compared to traditional sieves significantly reduces total cost of ownership.

Energy efficiency and resource optimization contribute to sustainable production goals. 15-20% less energy consumption per ton provides advantages both in terms of environmental impact and operating costs.

Return on investment analysis typically shows a period of 2-3 years. Increased efficiency, reduced operating costs, and improved product quality quickly cover the investment cost.

Industrial Applications and Usage Areas

Large-scale flour mills and integrated facilities are the main users of Titanius Square Sieve. High-capacity models are ideal for meeting the cleaning needs of large facilities.

More compact models are offered for medium and small-scale mills. Even for lower capacity businesses, the advantages of square form design are valuable.

High-capacity grain processing facilities, feed mills, and grain storage facilities are other common usage areas. The durability and high performance of Titanius Square Sieve provide reliable operation even in challenging industrial environments.

In applications for different grain types, Titanius Square Sieve offers flexibility. In addition to basic grains such as wheat, corn, and barley, it can also be optimized for legumes and special grains.

R&D and Innovation Process

The development story of Titanius Square Sieve began with Tanış A.Ş.’s experience in the milling sector and the search for solutions for customer needs. As stated in our vision, this product, which emerged by “keeping production technology and innovation at the forefront” and “making corporate investment in R&D,” is a milestone in the sector.

Tanış A.Ş.’s R&D studies in sieve technology have focused on material science, vibration engineering, and flow dynamics. Maximizing the advantages of square form and applying the potential of titanium alloys to sifting technology is the result of a research process spanning many years.

Improvements made based on customer feedback are the foundation stone of the product’s continuous evolution. Since the first generation Titanius model, significant improvements have been made in areas such as vibration control, ease of sieve change, and noise level in light of user experiences.

Studies on next-generation sieve technologies have focused on IoT integration, automatic adjustment systems, and smart monitoring solutions. New generation Titanius models compatible with Industry 4.0 concept, offering data analysis and remote monitoring capabilities, will be available in the near future.

Customer Experiences and Success Stories

One of the customer references using Titanius Square Sieve is ABC Milling, one of Turkey’s leading flour producers. After replacing their traditional sieves with Titanius Square Sieve, they managed to increase their cleaning capacity by 30% while reducing their energy consumption by 18%.

Another example of projects that achieved performance improvement is a mill processing high-moisture wheat. Thanks to Titanius Square Sieve, they eliminated clogging problems even under challenging conditions and achieved uninterrupted production opportunity.

Case studies and efficiency improvement examples demonstrate the value of Titanius Square Sieve under different operating conditions. A feed mill reported a 70% reduction in maintenance costs and a decrease in waste rates from 2.5% to 0.8% after three years of use.

User satisfaction and feedback are the real measure of the product’s success. 95% of our customers stated that they would choose Titanius Square Sieve again in future projects.

Frequently Asked Questions

How much energy does Titanius Square Sieve consume?

Depending on model size, it has motor power between 2.2 kW and 5.5 kW. Energy consumption per ton is on average 15-20% lower compared to traditional sieves.

How long does it take to change sieve surfaces?

Thanks to the quick-changeable cassette system, sieve surfaces can be changed within 10-15 minutes. This operation does not require special tools and can be easily performed by one operator.

Can the same sieve be used for different grain types?

Yes, the same sieve unit can be used for different grain types, but changing sieve surfaces and adjusting vibration parameters may be necessary. The Tanış engineering team helps you determine the optimum configuration for each grain type.

What is the maintenance frequency of Titanius Square Sieve?

Under normal operating conditions, monthly simple controls and annual comprehensive maintenance are sufficient. Thanks to titanium reinforcement technology, it requires less maintenance compared to traditional sieves.

How long does installation to my existing facility take?

A typical installation can be completed within 1-2 days. This time may vary depending on existing infrastructure and the condition of connection points. A detailed site inspection is conducted before installation to provide an exact time plan.

How long does the return on investment take?

Depending on operating conditions and the efficiency of the existing system, the typical payback period is 2-3 years. Energy savings, reduction in maintenance costs, and increased product quality ensure rapid return of investment.