Vibro Bran Brush

Vibro Bran Brush: Efficient Bran Processing with Vibration Tech

In the modern milling sector, efficiency and quality are the most important factors determining competitiveness. The Vibro Bran Brush developed by Tanış A.Ş. is starting a new era in bran processing processes with its revolutionary vibration technology. Our system, designed with advanced engineering solutions, maximizes your mills’ yield while minimizing your operating costs.

Vibro Bran Brush is an innovative machine that performs the flour separation process from bran in the milling process using vibration technology. This technology, which goes beyond traditional brushing systems, provides higher efficiency by utilizing the physical advantages of mechanical vibrations in bran cleaning.

The system transmits controlled vibration to brush elements through a specially designed vibration motor. This vibration movement increases the contact effectiveness of brushes with the bran surface, providing more effective cleaning with lower pressure compared to traditional systems. As a result, flour particles remaining on bran are separated more efficiently.

Unlike traditional bran brushes, since Vibro Bran Brush operates with less mechanical pressure, both brush element life is extended and the risk of bran breakage is reduced. This feature ensures cleaner bran-flour separation and higher quality final product.

The vibration technology at the heart of Vibro Bran Brush offers groundbreaking advantages in bran cleaning process. This innovative approach exceeds the limits of traditional methods and sets a new standard in milling processes.

Increased brushing efficiency through vibration effect ensures more effective separation of flour particles on bran. High-frequency vibrations create micro movements on the bran surface, cleaning flour in areas that fixed pressure systems cannot reach. This way, 15-20% more flour is obtained compared to traditional systems.

Low energy consumption and efficient operation are among the important advantages of Vibro Bran Brush. Vibration technology provides energy savings up to 30% compared to traditional systems. Thanks to its design that reduces wear and tear, equipment life is extended and maintenance costs are minimized.

The vibration mechanism of Vibro Bran Brush has adjustable vibration frequency in the range of 30-60 Hz and controllable amplitude between 0.5-2 mm. These parameters ensure maximum efficiency is achieved under different product types and processing conditions.

The operator can optimize vibration frequency, amplitude, and brushing time according to the product being processed through the digital control panel. This flexibility means optimum performance under all conditions.

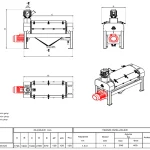

Technical Specifications and Performance Values

Vibro Bran Brush is offered in various models to meet different capacity needs. Basic technical specifications are summarized in the table below:

| Model | Capacity (tons/day) | Dimensions (W×L×H) | Motor Power (kW) | Vibration Frequency (Hz) | Weight (kg) |

|---|---|---|---|---|---|

| TVKP-35/50 | 40-50 | 1.5×2.1×1.8 m | 4 | 30-50 | 950 |

| TVKP-56/100 | 50-75 | 1.8×2.4×1.9 m | 7,5 | 30-60 | 1250 |

| TVKP-56/125 | 50-75 | 2.0×2.6×2.0 m | 11 | 30-60 | 1500 |

All our models have the following standard features:

- Stainless steel body structure (AISI 304 quality)

- High-strength special alloy vibration motor

- Wear-resistant composite brush elements

- Digital frequency control and monitoring system

- Adjustable vibration amplitude

- Integrated vibration isolation system

- Touch screen control panel

Model Options and Capacity Alternatives

VKF-100 and VKF-200 models are ideal for small and medium-scale mills. These models are optimized for facilities with daily wheat processing capacity of 100-250 tons. Thanks to their compact structures, they offer installation opportunity with minimum space requirement.

VKF-300 and VKF-400 models have been developed for large-scale flour mills. These high-capacity systems are ideal solutions for integrated facilities with daily processing capacity of 250-500 tons. They provide uninterrupted production with their reinforced structures and advanced control systems.

Flour Yield and Efficiency Increase

The most important contribution of Vibro Bran Brush to milling processes is increasing flour yield and efficiency. Thanks to vibration technology, more flour is separated from bran compared to traditional systems, providing a significant increase in total yield.

Increased flour separation efficiency through vibration effect ensures more effective cleaning of flour particles remaining on bran. The amount of flour discarded with bran in traditional systems is minimized, obtaining more flour from the same amount of wheat. Field tests conducted show that using Vibro Bran Brush provides an increase of 1.5-2.5% in total yield.

The yield increase obtained in different wheat types varies according to wheat characteristics. Yield increase of 2-2.5% is observed in hard wheats, while this rate is between 1.5-2% in soft wheats. This increase creates significant economic value especially in high-capacity mills.

Performance and Efficiency Data

The performance of Vibro Bran Brush has been comprehensively verified through laboratory tests and field applications. Comparative analyses with traditional bran brushing systems reveal the following performance advantages:

- 1.5-2.5% increase in flour yield

- 45% reduction in flour residue in bran

- 200% increase in brush element life

- 30% reduction in energy consumption

- 50% reduction in maintenance needs

This data was obtained as a result of comprehensive field tests conducted at 15 mills of different capacities over a 12-month period.

Effect on Product Quality

Vibro Bran Brush, in addition to yield increase, also has a positive effect on the quality of produced flour. Thanks to precise brushing provided by vibration technology, flour quality is preserved while yield is maximized.

One of the most important advantages of vibration technology is that it performs flour separation from bran with lower mechanical pressure. This way, the physical structure of flour particles is preserved and starch damage is minimized. As a result, optimum flour quality is obtained along with high yield.

Preservation of nutritional values is another important advantage provided by Vibro Bran Brush. Low-pressure vibration technology preserves wheat’s natural nutritional values, providing healthier flour production.

Energy Efficiency and Environmental Advantages

Vibro Bran Brush stands out not only with its technical superiority but also with the energy efficiency and environmental advantages it offers. It minimizes your operating costs while reducing your mills’ carbon footprint.

Low power consumption is one of the important advantages of vibration technology. Vibro Bran Brush, which provides energy savings up to 30% compared to traditional bran brushing systems, consumes much less electricity compared to standard systems of the same capacity. This saving provides a significant reduction in your annual energy costs.

Measurements conducted at a mill with 250 tons/day capacity showed that 45,000 kWh electricity savings per year was achieved compared to traditional systems. This saving creates a significant cost advantage when calculated with average electricity prices.

Installation and System Integration

Vibro Bran Brush is designed to be easily integrated into existing mill lines. Thanks to its modular structure, it can be included in your system with minimum interruption.

The system can be directly mounted in place of your mill’s existing bran processing unit or added as a parallel line. In both cases, installation is completed with minimum line modification.

Minimum space requirement and compact design ensure effective use of limited spaces within the mill. The placement dimensions of Vibro Bran Brush are optimized and it occupies 20% less space compared to traditional systems.

Maintenance and Service Advantages

Vibro Bran Brush minimizes your operating costs with its low maintenance requirements and long service intervals. Thanks to vibration technology, mechanical wear is minimized while equipment life is maximized.

Reduced maintenance needs mean 50% less maintenance intervention compared to traditional systems. Thanks to the vibration principle, brush elements wear less and replacement frequency decreases. This feature both reduces maintenance costs and minimizes production interruptions due to maintenance.

Brush replacement and periodic controls are easily performed thanks to modular design. Brush elements can be changed quickly and easily with special connection system. These design features minimize maintenance time and increase production efficiency.

Economic Advantages and ROI Analysis

Vibro Bran Brush investment amortizes itself in a short time with the efficiency increase and operating cost savings it provides. Detailed ROI (Return on Investment) analysis clearly reveals the financial advantages of the investment.

Operating cost savings are achieved through reduced energy consumption, less maintenance needs, and long-lasting components. 25-30% savings are achieved in annual operating costs compared to traditional systems.

Financial return of yield increase is the most important economic advantage of Vibro Bran Brush investment. Average 2% yield increase means 1250 tons of additional flour production annually in a mill processing 250 tons of wheat daily.

Investment payback period is between 10-14 months on average, although it depends on operating capacity and working conditions. This period can be even shorter in high-capacity facilities.

Customer Experiences and Success Stories

Vibro Bran Brush, preferred by Turkey’s leading flour producers, makes a difference with the value it offers to its users. Here is a customer experience:

Anadolu Flour – Konya: “With Tanış Vibro Bran Brush, we achieved a 2.3% increase in our yield. This increase created significant additional revenue on an annual basis while we did not compromise our product quality. Our investment amortized itself in 11 months.” – Mehmet Yılmaz, Production Manager

Frequently Asked Questions

Can Vibro Bran Brush be integrated into my existing system?

Yes, thanks to its modular structure, it can be easily integrated into most existing mill systems. Our Tanış engineering team ensures smooth installation by creating an integration plan specific to your facility.

What is the average life of brush elements?

Although it depends on operating conditions, the average life of brush elements is 8-10 months. This period can be extended with regular maintenance and correct use.

How much yield increase can I expect?

Depending on the type of wheat processed and the efficiency of your existing system, 1.5-2.5% yield increase is achieved. More precise information can be given as a result of analysis to be conducted at your facilities for exact values.

What is the investment payback period?

Although it depends on facility capacity and operating regime, average payback period is between 10-14 months. This period can be even shorter in high-capacity facilities.

Is it suitable for different grain types?

Yes, Vibro Bran Brush shows effective performance in processing different grain types such as corn, rye, and barley in addition to wheat. Operating parameters can be optimized for each grain type.